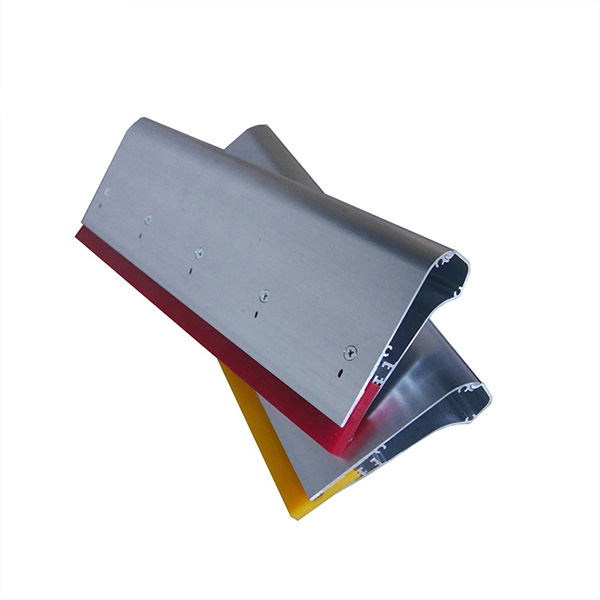

Ergo Force Aluminum Handle Squeegee operating:

Scrap cleaning requirements:

1, Only use weakly diluted solvent cleaning;

2, Do not put the glue in the solvent soak, even if the solvent is not corrosive, please wear gloves with clean cloth cleaning;

3, Do not use the following solvents

cyclohexanone, MEK, triglycerides, ISOPHORONE, ethyl ethoxylate

Butyl propionate, VYNIL, PYROLIDORE, carbohydrates

Grinding:

1, Grinding scraping to clean, dry, it is best to place after 24 hours.

2, Plastic scraping should be fixed in its supporting the use of aluminum clip on the grinding.

3, Whether the grinding machine is a belt or wheel type, are the use of medium sand (110 head -130 head),if the sand is too fine will lead to blocking or overheating, fine sand can do the final stage of grinding to suit the high precision print.

Storage:

1, Can not be a long time to soak the glue in the solvent.

2, Plastic scraping the printing side need to be replaced to use. As a result of contact with the solvent, rubber scraping began to be corrosion, and then by after a period of time / pressure, the hardness of the plastic scraping will become soft, blade structure damage. So every 2-4 hours it should be used to flip the use of plastic scraping after the use of the plastic is a new printing edge.

3, Plastic scraping in use, should be attached to the ink on the clean, dry. Usually with a mild diluent cleaning.

Our company as a Screen Printing frame supplier in china ,if you need that pls contact us.